Benefits & Future Scope of Cloud Computing In Manufacturing Industry

The arrival and wide acceptance of advanced technologies like AI, ML, Big Data, Blockchain, and more have made cloud computing a pivotal force in the digital transformation of various industries. Within a short period, cloud computing has become a priority of most organizations. The pandemic has further raised the demand because organizations of all sizes started adopting cultures like work from home, remote management, and more.

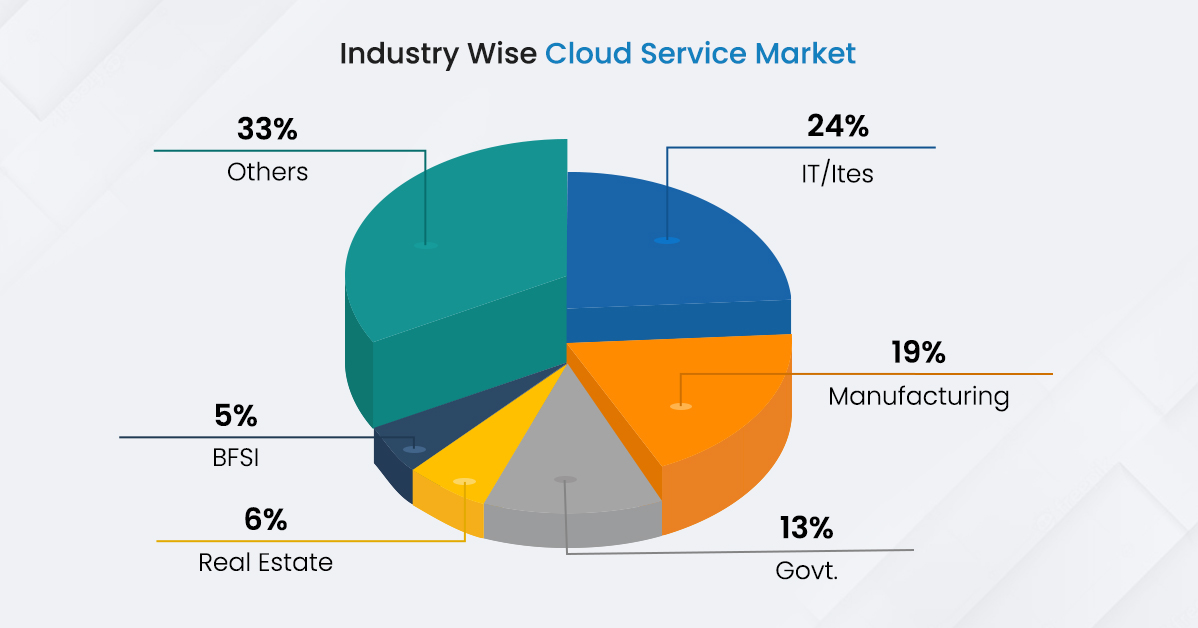

But, the phenomenon of cloud computing is not that new for sectors like IT, Finance, and e-commerce as they have been using cloud-based products for a long time and are benefiting from it now. Amidst all this transformation, there still are sectors like the manufacturing industry that are coping with the scenario and have a long way to go to utilize the full potential of cloud computing and with the pandemic not showing any signs of immediate halt, no industry would want to get hampered again with any possibility of lockdowns.

In that case, the coming year can be crucial to get that required business boost and achieve the set business milestones. As far as the stats are considered, according to a report by Nasscom, enterprises’ spending on cloud computing is expected to rise to $7 Bn by 2022. Another report by Market research future states that the manufacturing sector is forecasted to attain $111.9 Bn worth of cloud computing investment by 2024. These stats are evident enough to signify the increasing demand and speedy adoption of cloud computing-related services in the manufacturing sector. Apart from this, the FDI inflows in India in the previous decade make it clear that the demand from the manufacturing and the IT sector in the country is further going to rise, hence the sector needs to be future-ready in that sense.

The road ahead of cloud computing in the manufacturing sector

Talking about the manufacturing sector, the key always has been to fulfill speedy delivery of larger orders & requirements all being affordable and flexible at the same time. These needs of the industry can be fulfilled by cloud computing, as for the sector, connectivity of all different elements of every section, right from procurement to production and later to storage, is a key requirement. In that case, manufacturers can utilize various cloud services to streamline everything and stay connected with the end consumers at the same time. Yes, there is a significant rise in the number of manufacturers using a combination of public and private clouds, and the demand is on the rise. Then for those looking out for or planning to incorporate cloud computing in their business flow, they couldn’t have asked for a better time than now, and staying back will result in missing out on targets a big time.

If you, as an industry person, are still skeptical about the integration of cloud computing or have some doubts regarding the same, then let us flash a spotlight on some factors that would lead to better performance and productivity of your enterprise as a whole.

Improved Co-ordination In The Production Line

Think of a situation where the purchasing department is unable to fulfill the requirement of a fixed order due to some miss communication, or the production line management fails to fulfill the delivery requirement in time. All this happens because several manufacturers are still dependent on legacy software connected with separate data silos. On the contrary, with cloud-based platforms and applications, manufacturers can remove these silos and coordinate them irrespective of geographical limitations. This in turn helps in a well-coordinated and orchestrated production line. Apart from this advanced tech like AI, IoT, Geo-Processing, and many similar technologies are making their way and will mark a wider presence in 2022, which can assist manufacturers in timely identifying failures in equipment, saving both cost and time.

Achieving Lean Management Through Time and Waste Management

Even on today’s date, most of the manufacturers are functioning on a labor-intensive setup that bears too much cost and has an unpredictable nature of productivity. As with more labor comes more wayward outcome. In short, what the manufacturing industry needs is the minimal human interface in the overall infrastructure. This doesn’t mean that manufacturers should reduce the workforce, what they need to do is reduce the dependency. All to manage demand and supply accordingly. Cloud-based ERP, along with other tools like CRM, will speed up the production process and enhance the overall accuracy.

One key thing is that the manufacturing sector has already been hampered a lot in two consecutive financial years and they do need to cover up on all aspects in the coming financial year and for that speeding up and streamlining their production will be the prime necessity and cloud computing can be the needed catalyst in the due process. As with the cloud what you get is a unified interface to track the whole process, whether of purchase, production, or delivery. Everything is accessible and tracked by everyone that too wherever and whenever needed.

Innovation has been the real driving force behind the increased cloud adoption in the manufacturing industry. As with the implementation of cloud-based ERP systems through web applications, software, and various mobile apps, manufacturers can move away from the traditional systems allowing them to create and imbibe new technologies and capabilities within their units and with the onset of the New Year, new technologies like AI, ML, and voice-based searches are estimated to be an inseparable part of every-day business.

The major manufacturing issue is the oscillation in production throughout the year, i.e., the unstable production. It does affect the overall functioning and business relations on a large scale. With cloud-based applications, manufacturers can monitor and regulate the production and get to the desired milestones as and when required. It can even be of big help to understand the requirement of the raw materials as per the demand of production. Just think of an order update, flagged to the purchase, production, and delivery department all at once. Leading to proper coordination across the departments and streamlining the production and supply of the unit without further ado.

To Conclude

Cloud computing is the phenomenon of the present time and no more of the future. If the manufacturers don’t alter and adopt now, they might fall behind in the race. Not to forget about the government’s emphasis on manufacturing and IT. And with cloud service providers like ESDS Software Solutions Ltd. offering various products and services for various requirements. It will be better for manufacturers to implement cloud-based software and applications as soon as possible and benefit in the coming year by being at least in the race, if not the front runner.