AI, the Digital Transformation Catalyst in Manufacturing Industry

A new edition to the business world, Artificial Intelligence has proved to be a driving force of a new round of technology and the industrial revolution. According to a survey, 23% of businesses have incorporated AI-powered algorithms into processes and service offerings. Making its way into the manufacturing industry, AI is projected to increase labour productivity by 40%, enabling efficient use of time. Intelligent manufacturing is playing a pivotal role in upgrading the industrial sector of developed and developing countries.

Artificial Intelligence Techniques for Intelligent Manufacturing

1. Knowledge-Based Systems: Knowledge-based systems enable to integrate some degree of human intelligence with manufacturing systems. The algorithm represents human knowledge in the form of IF-THEN production systems. The system is directed towards analysing and redesigning manufacturing systems.

2. Neural Network: Based on the concept of working of the brain, Neural Network has gained popularity in the manufacturing environment. Artificial neural network benefits the manufacturing environment by allowing parallel-distributed computation, robustness, etc. The technique widely classifies and optimises the situations. The network is trained using historical data, determining the suitable configuration of a hidden network.

3. Fuzzy Logic: Fuzzy logic enables representing and processing imperfect information like linguistic statements in the decision-making models. It allows designers in the manufacturing environment to explore changeability level decisions.

4. Genetic Algorithms: Genetic algorithms are used to solve constrained and combinatorial optimisation problems in the manufacturing industry.

5. Case-based Reasoning: The Case-based Reasoning (CBR) is an interactive problem-solving approach consisting of a history of problems and the solutions applied. It tackles new issues using the past results, taking advantage of analogies between similar cases.

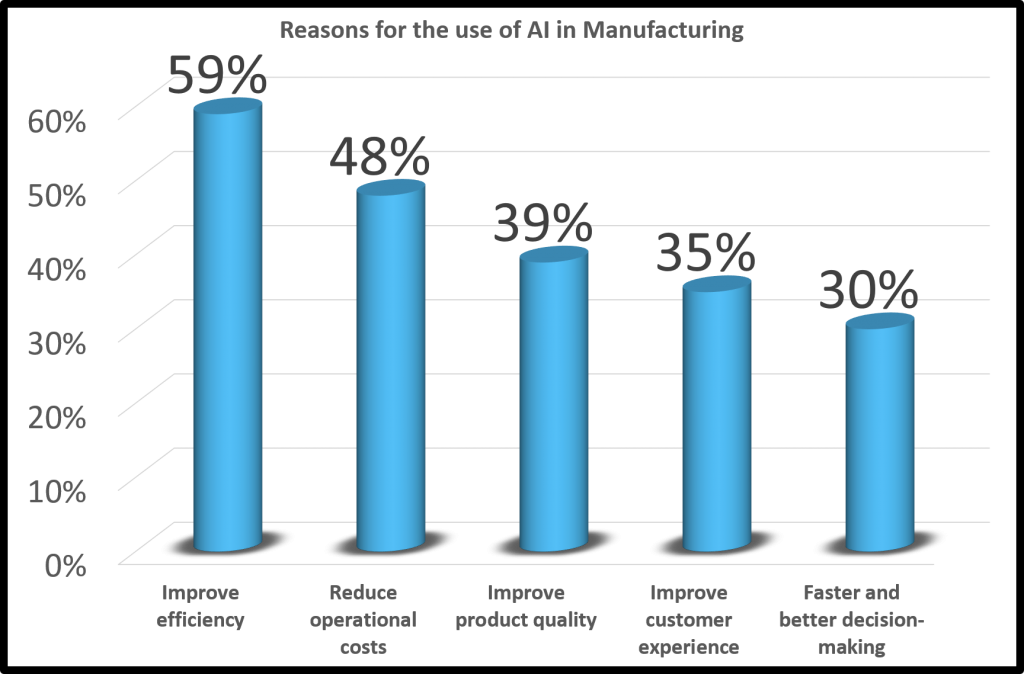

Manufacturing Industry Leveraging Artificial Intelligence

1. Improved Efficiency:

The manufacturing industries across the globe are integrating AI to enhance the efficiency of manufacturing processes. AI, along with machine learning, can anticipate information, refine processes and track incongruities of the supply chain right from the raw material to finished products. It uses an RFID tracking system, enabling the automatic tracking of materials without the need to be tracking with a bar code reader. AI helps to automate the process of monitoring the quantity of material used, temperatures, minimising errors and downtime.

Let us see how AI helps to enhance manufacturing

I. It helps precise analysis and testing of mathematical models of production and outcome possibilities. AI and machine learning can together reduce the overall inventory of 20% to 50%.

II. Investing in predictive maintenance solutions improves operational efficiency by predicting future equipment failures. AI-enabled predictive maintenance is capable of reducing maintenance cost by 10% and downtime by 20%.

III. AI-enabled personalised manufacturing enables industries to personalise products and services dependent on customer preferences.

2. Reduce Operational Cost:

AI automates the routine processes reducing the operational cost and machine downtime. AI-powered machines are capable of partially or fully replacing employees by automating the tasks and reducing human errors.

i. Artificial Intelligence reduces the cost of manufacturing industry by minimising the human errors that may postpone the product release and maybe a huge cost to the company.

ii. Artificial intelligence helps you to manage your customers intelligently increasing your brand loyalty. This helps the organisation to reduce expenses on customer service.

iii. 24X7 service sounds great but is expensive and requires employees trained in different languages and available in different shifts. AI-enabled chatbots offer service 24X7 in diversified languages. These chatbots reduce employee expenditure.

3. Improved Product Quality:

Integrating Artificial Intelligence in the production process results in high-quality products even under the constant pressure of market deadlines. The production teams can be notified about the emerging faults in the functioning of machines using an AI algorithm.

I. AI algorithms trained on historical entities and processes, attributes and decisions can produce the optimal planning and production strategies. The algorithms are trained according to the strict manufacturing standards ensuring better product quality.

II. AI has changed the way we create and design products. Integrating AI algorithms in product designing process explores all possible design alternatives and creates a design that meets the goals of engineers.

4. Improve Customer Experience:

Customer experience is key to the success of the digital transformation. AI improves customer experience by analysing customer data and personalising the products.

I. AI-powered chatbots and virtual assistants solve customer queries in a minimal amount of time. It reduces the delay in answering customer queries, thus enhancing customer service.

II. AI algorithms enhance customer experience, offering personalised content by analysing our search history.

5. Faster and Better Decision Making:

Artificial Intelligence, along with databased business models, serve an opportunity in manufacturing decision making.

I. AI techniques offer reliable insights into your customer personas, enabling the projection of consumer behaviour. AI decision-making system supports the real-time decisions providing accurate data.

II. Artificial Intelligence enhances contact management, consumer data recording & analysing and lead ranking offering customer lifetime value.

Conclusion

AI enhances manufacturing efficiency at reduced

costs. It automates the manufacturing processes reducing the probability of

human errors and product or machine defects. Serving as the key driver for

manufacturing success, AI has optimised the product quality, supply chain and

factory throughput in the digitally driven industrial revolution.

- Digital Transformation Paves the Way for the Finance Industry - July 29, 2021

- Embracing Change – How Banks are Adopting Digital Innovation - April 19, 2021

- How the Indian Education Sector is Embracing Cloud Computing - November 13, 2020